Description

A pollution control device used to remove particulate matter from industrial exhaust gases.

Pre-ESP Era

❑Before the invention of the electrostatic precipitator, industrial processes released harmful pollutants directly into the atmosphere.

❑Air pollution caused respiratory diseases, environmental degradation, and reduced air quality.

❑The need for a solution led to the development of electrostatic precipitation technology.

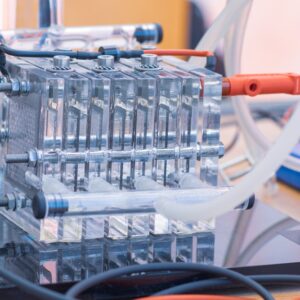

Electrostatic Precipitator

❑An electrostatic precipitator is a device that utilizes the principles of electrostatics to remove particulate matter (dust, smoke, ash, etc.) from industrial exhaust gases.

❑It operates by giving an electric charge to the particles, causing them to be attracted to and collected on charged plates or electrodes.

Applications

1.Power Generation Plants:

Electrostatic precipitators play a crucial role in power generation facilities, whether they rely on fossil fuels such as coal or oil, or utilize biomass. EPS units effectively capture fly ash, smoke, and other particulate matter emitted from the combustion of fuel. By removing these pollutants, electrostatic precipitators prevent their dispersion into the atmosphere and support compliance with emissions regulations. This ensures cleaner air quality and reduces the environmental impact of power generation plants.

2.Cement and Steel Manufacturing

In cement production plants, kiln exhaust gases containing harmful dust, heavy metals, and other pollutants are effectively treated by electrostatic precipitators. These devices assist in reducing the emission of particulates, thus safeguarding the health of workers and maintaining compliance with air quality regulations.

3. Chemical and Petrochemical Plants:

Chemical and petrochemical manufacturing processes often produce hazardous by-products, including volatile organic compounds (VOCs) and fine particulates. Electrochemical precipitators can be integrated into these facilities to efficiently control and address these emissions. By effectively removing VOCs and particulate matter from the exhaust gases, electrostatic precipitators ensure a healthier workplace environment, protect the surrounding communities, and enable compliance with stringent environmental regulations.

4. Waste Incineration Facilities

Waste incineration plants face significant challenges in managing air pollution generated from the combustion of waste materials. Electrostatic precipitators are highly effective in capturing fly ash, heavy metals, dioxins, and other harmful pollutants. By controlling these emissions, the precipitators minimize risks to both human health and the environment. Their implementation ensures compliance with stringent emissions standards, thus promoting sustainable waste management practices.

5. Pharmaceutical Industry

ESPs are employed in pharmaceutical manufacturing processes to capture and remove fine dust and particulate matter generated during drug formulation and production.

Advantages

✓ High efficiency in removing fine particulate matter (>99% removal efficiency).

✓ Low operating costs compared to other pollution control devices.

✓ Long operating life and minimal maintenance required.

✓ Reduces environmental pollution and improves air quality.

✓ Can be customized to suit different industrial applications.

Concerns and Considerations

1. ESPs have limitations in capturing fine particles (less than 1 um).

2. Installation and operational complexities may arise due to their large size and weight.

3. Proper maintenance is crucial for consistent performance.

4. Energy consumption may be a concern for larger systems.

Types of Electrostatic Precipitator

1. Plate-Type Electrostatic Precipitator (ESP)c

The plate-type ESP is the most common and widely used design. It consists of two sets of electrodes: a series of positively charged plates and negatively charged plates. As the gas flows through the unit, the particulate matter is electrically charged and attracted to the grounded collection plates. The captured particles are periodically removed by rapping or mechanical means.

2. Tubular-Type Electrostatic Precipitator

Tubular ESPs are utilized when the gas stream carries larger particulate matter or material prone to fouling. They consist of cylindrical tubes with a wire electrode running down the center. The charged particles adhere to the inner surface of the cylindrical tubes, and periodic cleaning or washing is required to remove the accumulated particulate matter.

3. Wet Electrostatic Precipitator (WESP)

WESPs are primarily used for applications involving high moisture content gas streams or particulates that tend to adhere and resist dry collection. They employ a liquid scrubbing process to remove particles. The gas stream passes through an electrode chamber, where the particles are charged and then subjected to a water spray. The charged particles are then collected in a manner similar to other ESP types.

4. Dry Electrostatic Precipitator (DESP)

DESPs are commonly used in applications with dry, high-temperature gas streams. These electrostatic precipitators utilize metallic electrodes to charge the particles in the gas stream. The charged particles are then collected on grounded collection plates or tubes, while the clean gas exits the system.

General Specification:

The electrostatic precipitator (ESP) is a highly efficient air pollution control device widely used in industrial applications to remove particulate matter from gas streams. It operates on the principle of electrostatic attraction, capturing and collecting fine particles suspended in the exhaust gases produced by industrial processes.

1. Purpose:

The electrostatic precipitator aims to eliminate harmful particulate matter and improve air quality, ensuring compliance with emission standards and regulations. It can effectively capture various types of particles, including dust, fly ash, smoke, and other industrial pollutants.

2. Design and Construction:

a. Housing: The ESP is typically housed in a sturdy metallic casing to withstand harsh operating conditions. It includes access doors for maintenance and inspection purposes.

b. Collecting Plates: The precipitator consists of a series of parallel plates, known as collecting plates, made of durable materials such as metal or ceramics. These plates are negatively charged, creating an electrostatic field that attracts and collects particles.

c. Discharge Electrodes: Adjacent to the collecting plates are discharge electrodes, which generate the high-voltage corona discharge that charges the particles, enabling them to adhere to the collecting plates.

d. Insulation: Suitable insulation materials are used to ensure electrical safety and prevent leakage of the high voltage used in the ESP.

e. Rapping System: To dislodge the accumulated particles from the collecting plates, a rapping system or mechanical vibrator is employed. This helps maintain the efficiency of the precipitator by preventing excessive particle buildup.

3. Control and Monitoring:

a. Power Supply: The ESP requires a reliable and stable high-voltage power supply to generate the necessary electrostatic charge.

b. Control System: A control panel and programmable logic controller (PLC) are utilized to manage the operation of the precipitator, enabling adjustment of parameters and monitoring of performance.

c. Monitoring Instruments: Instruments such as particle analyzers, pressure and temperature sensors, and opacity monitors are incorporated to provide real-time data on emission levels, system integrity, and overall performance.

4. Efficiency and Performance:

The performance of an electrostatic precipitator is measured in terms of its collection efficiency, which indicates the effectiveness of particle removal from the gas streams. Factors affecting efficiency include voltage levels, gas velocity, geometric design, and resistivity of the particles to be collected. The ESP should be designed to achieve high collection efficiencies, typically above 99%.

5. Maintenance and Safety:

Proper maintenance and safety practices are crucial for the efficient and safe operation of the ESP. Regular inspection, cleaning of collecting plates, and checking of electrical connections are required. Safety features like interlocks, grounding, and overload protection should be incorporated to ensure worker safety and prevent damage to the equipment.

Note: Specific design and operational requirements of an electrostatic precipitator may vary depending on the intended application and industry standards.

Concluding Remarks

Despite the few disadvantages and concerns surrounding electrostatic precipitators, their advantages remain undeniable. Their efficiency, adaptability, longevity, and eco-friendliness make them an indispensable tool in combating air pollution and ensuring a cleaner, healthier future for all. As we continue to priori sustainable practices, it is imperative to recognize the potential of electrostatic precipitators as essential allies in our ongoing battle against environmental degradation.