Description

Filter press is a separation process that uses pressure to filter liquids and solids. It works by pumping the slurry into the press, which is then filtered through a series of plates and frames until the desired separation is achieved.

Operating principle of the machine

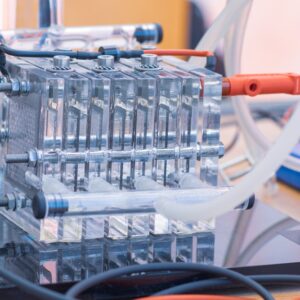

Filter press separates solid particles from liquid using a series of filter plates and frames. High pressure forces the liquid through the filter cloth, leaving behind the solids.

Main parts of the filter press machine

- Plate and frame filter press

- filter cloths and plates

Hydraulic System

The Industrial Filter Press Machine is a specialized tool used in various industries for solid-

liquid separation .It efficiently separates liquid from a mixture containing solid particles using pressure filtration.

How does a filter press machine work ?

A filter press machine is designed to separate liquids and solids using pressure filtration. It consists of a series of plates and frames

Importance of Industrial Filter Press Machine

• Industrial Filter Press Machines play a crucial role in many industrial processes.

• They remove impurities ,concentrate solids ,and recover valuable liquids.

• This ensures improved product quality, reduced waste, and increased efficiency, leading to cost savings.

Applications:

1. Mining and Metallurgy

For dewatering mineral concentrates and metal sludge

2.Chemical and Pharmaceutical

To separate solids from chemical reactions or to extract valuable components

3.Food and Beverage

For clarification of liquids, removal of impurities, and extraction of oils

4.Municipal Wastewater Treatment

For sludge dewatering and water purification

5.Oil and Gas Industry

To separate oil from water and remove solid particles

Types of Industrial Filter Press Machines

There are four main types of Industrial filter press machines: plate and frame filter press, recessed chamber filter press, membrane filter press, and vacuum filter press. Each type has unique features and advantages for different industrial applications.

1.Recessed Plate Filter Press

Consists of plates with a concave depression and a hole in the center .Solids are trapped in the recessed chamber formed between the plate and the filter cloth. Used for dewatering and solid-liquid separation of various suspensions .

2.Membrance Filter Press

Uses a flexible membrance to compress the filter cake .Products dryer filter cakes compared to other filter press types .Ideal for wastewater and sludge treatment applications .

3.Plate and Frame Filter Press

Consists of filter plates and frames .Ideal for filtering high volumes of bulk solids .Commonly used in food , chemical , and pharmaceutical industries .

4.Automatic Filter Press

Uses an electric motor to automatically open and close the filter plates .Offers fast and efficient filtration with minimal supervision.Ideal for large-scale industrial operations .

Specifications for Industrial Filter Press Machines

1.Filtering Area

Range from a few square meters to several hundred square meters.

2.Filtering Pressure

Varies from high to low pressure based on the desired filtration efficiency .

3.Cake Thickness

The thickness of the filter cake formed during the process .

4.Cake Moisture Content

The moisture content of the discharge solids .

5.Cycle Time

Time taken for each filtration cycle .

Usage

The usage of an industrial filter press machine involves several steps .

Pre-filling

The filter press is prepared by inserting filter media and ensuring proper alignment .

Filling

The mixture containing solids and liquid is introduced into the press .

Filtration

Pressure is applied, forcing the liquid to pass through the filter media, leaving solids behind.

Cake Removal

The solid cake is separated from the press plates .

Washing and Drying

Additional steps may be taken to wash and dry the filter cake, depending on the application.

Maintenance and troubleshooting

Clean the machine regularly , inspect the filter plates , check the hydraulic pressure , and replace worn out parts .Troubleshoot any leaks and low filtration rates .

Conclusion :

The industrial Filter Press Machine is a vital tool in various industries , delivering efficient solid-liquid separation ,improved product quality , and cost savings .