Description

Heat exchanger is a system that enables the transfer of thermal energy between fluids, without direct physical contact, to achieve desired temperature control or heat recovery.

Application

1. Industrial Processes

Heat exchangers are widely employed in industrial processes, particularly in sectors such as petrochemical plants and refineries. These industries require efficient heat transfer systems to facilitate the cooling or heating of various components, such as gases, liquids, and hazardous materials. Heat exchangers help maintain appropriate operating temperatures, enhance efficiency, and ensure the safe handling of substances.

2. Heating, Ventilation, and Air Conditioning (HVAC) Systems

Heat exchangers are integral components of HVAC systems used in both commercial and residential buildings. HVAC systems regulate indoor temperatures by transferring heat between the air inside and outside the building. Heat exchangers facilitate this process, allowing efficient and controlled transfer of heat, thereby ensuring comfortable indoor environments.

3. Power Generation

Heat exchangers are essential in power generation, including both traditional and renewable energy systems. In thermal power plants, they are used in steam generators to transfer heat from hot flue gases to water, thereby producing steam to power turbines. Heat exchangers are also employed in nuclear power plants to cool reactor cores. In renewable energy systems like geothermal or solar power, they aid in harnessing and utilizing heat from the Earth or the sun.

4. Process Industries

Heat exchangers play a crucial role in various process industries such as food and beverage, pharmaceutical, and chemical manufacturing. They are used in processes like pasteurization, sterilization, and cooling of products, ensuring safety, quality, and prolonging shelf life. Heat exchangers enable precise control over temperature and prevent product contamination.

5. Automotive Industry

Heat exchangers have widespread use in the automotive industry, primarily in engine cooling systems and air conditioning systems. In engine cooling, heat exchangers extract excess heat generated during combustion and transfer it to the surrounding air through radiators. In air conditioning systems, they facilitate the transfer of heat from the cabin to the outside environment, ensuring optimal temperature control.

6. Renewable Energy Systems

Heat exchangers are integral components in renewable energy systems, such as solar thermal collectors or biomass boilers. They enable the transfer of heat energy from renewable sources (like the sun or biomass) to working fluids like water or air, converting it into usable heat or electricity.

ADVANTAGES

1. Efficient thermal energy transfer leading to energy savings

2. Improved process efficiency and productivity

3. Compact design and space-saving capabilities

4. Temperature control and maintenance

5. Pollution reduction and environmental benefits.

6. Versatility and compatibility with different fluids

Concerns

• Fouling: Accumulation of unwanted deposits reducing efficiency.

• Corrosion: Potential for chemical degradation of heat exchanger materials.

• Pressure drop: Resistance to fluid flow causing energy losses.

• Maintenance: Regular cleaning and inspection to ensure optimal performance.

• Cost: Initial investment and operational expenses.

Types of Heat Exchanger

Shell and Tube Heat Exchangers

Shell and Tube Heat Exchangers are widely used devices that facilitate the transfer of heat between two fluids. They consist of a bundle of tubes enclosed within a cylindrical shell. One fluid flows through the tubes while the other flows around them, allowing for efficient heat exchange due to the large surface area provided by the tubes. These heat exchangers are commonly employed in various industrial processes, such as power generation, chemical manufacturing, and HVAC systems.

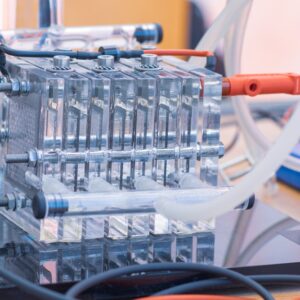

Plate Heat Exchangers

Plate Heat Exchangers are compact and efficient devices utilized for transferring heat between two fluids. They consist of a series of plates with alternating cold and hot fluid channels. The fluids flow on either side of the plates, allowing for effective heat transfer due to the extensive surface area and turbulent flow inside the channels. Plate heat exchangers are commonly used in applications where space constraints and high heat transfer rates are crucial, such as refrigeration systems, HVAC systems, and food processing.

Finned Heat Exchangers

Finned Heat Exchangers are heat transfer devices that incorporate extended surfaces, known as fins, to enhance heat exchange between two fluids. These fins provide additional surface area, which improves heat transfer efficiency by increasing the convection coefficient. Finned heat exchangers are commonly used in applications involving air cooling or heating, such as air conditioning systems, automotive radiators, and industrial heat recovery systems

Double Pipe Heat Exchangers

Double pipe heat exchangers, also known as hairpin heat exchangers, are simple and compact devices used for heat transfer between two fluids. They consist of two concentric pipes, one inside the other, with the fluid to be heated or cooled flowing through the inner pipe while the second fluid flows through the annular space between the pipes. Double pipe heat exchangers are widely used in applications requiring small heat transfer capacities and where space limitations exist, such as small-scale process industries and laboratory setups.

Refrigerant Condensers and Evaporators

Refrigerant condensers and evaporators are critical components in refrigeration and air conditioning systems. The condenser acts as a heat exchanger where the high- pressure refrigerant vapor is cooled and condensed into a liquid, releasing heat to the surrounding environment. Conversely, the evaporator facilitates the evaporation of the low-pressure liquid refrigerant, absorbing heat from the desired space or substance, thereby cooling it. These heat exchangers ensure the efficient operation of refrigeration systems by enabling the phase change of the refrigerant and facilitating heat transfer between the refrigerant and the surrounding medium .

Heat Exchanger Specifications

Specifications vary based on industry requirements

❖ Heat transfer area

❖ Maximum/minimum operating temperatures ❖ Pressure rating – Material compatibility

❖ Flow rate capacity

Installation

To install a heat exchanger, you will need to follow specific steps in a professional manner.

Here’s a step-by-step guide on how to install a heat exchanger:

1. Pre-installation Stage:

a. Evaluate the space: Examine the location where you plan to install the heat exchanger. Ensure that it has enough clearance, proper ventilation, and meets the necessary safety requirements.

b. Review the specifications: Understand the heat exchanger’s technical details, such as its capacity, flow rates, and connection requirements.

c. Gather the necessary tools and equipment: Equip yourself with the necessary tools and safety gear, such as wrenches, gauges, thermal paste, and pipe cutters.

2. System Preparation:

a. Turn off the power: Before starting any installation work, always ensure that the power is turned off to avoid any electrical hazards.

b. Drain the system: If you are replacing an existing heat exchanger, drain all fluids from the system and disconnect any associated pipes.

3. Mounting the Heat Exchanger:

a. Select an appropriate location: Determine the best location for mounting the heat exchanger, considering factors such as accessibility, adequate support, and proximity to other components (e.g., pumps).

b. Secure the heat exchanger: Use brackets or mounts to secure the heat exchanger firmly in place. Ensure that it is level and stable.

4. Connecting Pipes:

a. Cut pipes to the appropriate length: Use pipe cutters to cut pipes to the required lengths, ensuring accurate measurements.

b. Clean the pipe ends: Clean the pipe ends to remove any debris or burrs that could affect proper connections. c. Attach pipes to the heat exchanger: Connect the appropriate pipes to the heat exchanger, following the manufacturer’s specifications. Use appropriate fittings, such as couplings or compression connectors, to ensure secure connections.

d. Insulate the connections: Apply insulating material, such as thermal tape or foam, to the pipe connections to reduce heat loss.

5. Testing and Finishing:

a. Pressure test: Ensure there are no leaks in the system by conducting a pressure test according to industry standards or manufacturer guidelines.

b. Connect other components: Connect any additional components, such as pumps, valves, and control systems, as required.

c. Power up the system: Once all connections are confirmed secure and leak-free, power up the system and monitor its performance.

d. Inspect for proper operation: Observe the heat exchanger’s performance over time, checking for efficient heat transfer and compliance with specifications.

Remember, heat exchanger installations can have specific requirements depending on the type, size, and design of the system. Always consult the equipment manufacturer’s installation manual, industry standards, and local building codes for precise instructions and safety guidelines. If you lack expertise or experience, consider seeking assistance from a qualified professional.